Detail

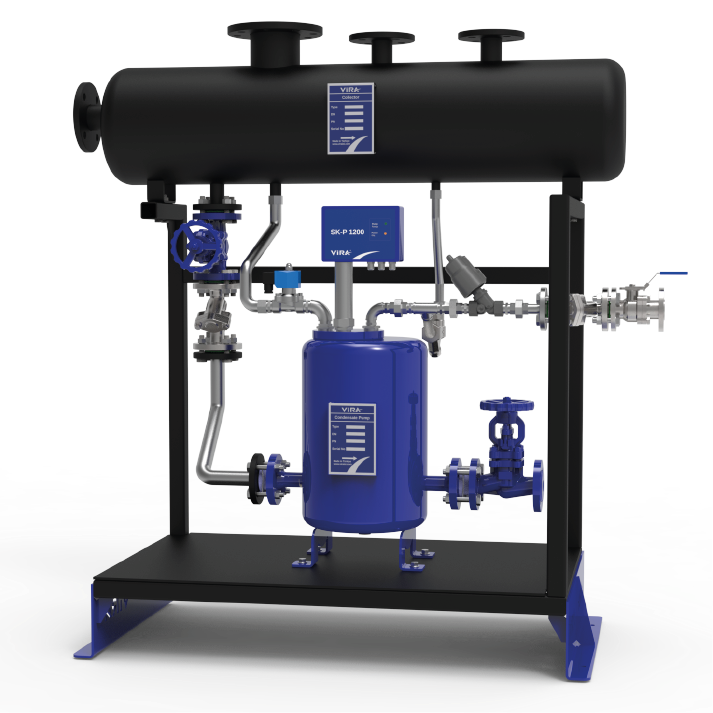

Compact, electronically controlled condensate pump for efficient and reliable condensate recovery.

| Body | : | Carbon Steel |

| Connection | : | Flanged |

| Size | : | DN 25 - DN 80 |

| Max. Working Pressure | : | 10 bar |

| Max. Working Temperature | : | 180 °C |

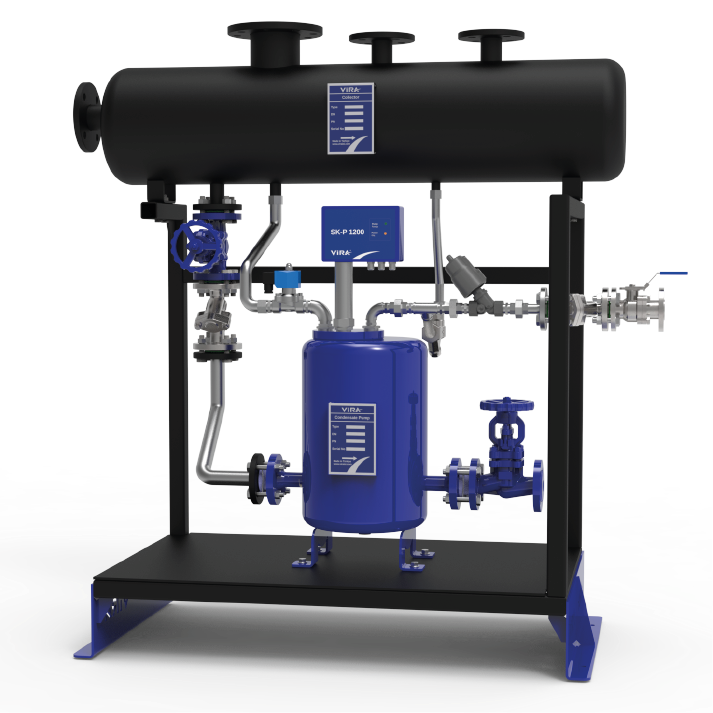

Compact, electronically controlled condensate pump for efficient and reliable condensate recovery.

| Body | : | Carbon Steel |

| Connection | : | Flanged |

| Size | : | DN 25 - DN 80 |

| Max. Working Pressure | : | 10 bar |

| Max. Working Temperature | : | 180 °C |

If you have any questions about our products, our solutions or need advice from our experts don't hesitate to contact us!